Impulse Tools

a step into future

The Toyota Production System (TPS) worldwide qualifies as benchmark for highly efficient assembly in most different branches of industry. Toyota successfully relies on impulse technology for years. Electronic controlled impulse wrenches of the Japanese specialist Yokota are not the tools for bolted joints of the future – they are the tools of today functioning like they should.

Whoever has watched the development of manual pneumatic nutrunners in the past decades, especially in the automobile and subcontractor industry, can realise a clear line from formerly used impact wrenches over shut-off tools right up to modern impulse wrenches. The advantages of conventional nutrunners – fast, lightweight and nearly reaction-free – had to be accepted with high noise level, vibrations, large torque tolerances plus the impossibility to measure tightening torque. The aggravation of statutory provisions, the manufacturer liability and the wish to use as small bolts as possible, which can be used up to yield strength, have made the application of impact wrenches more and more problematic. Further problems caused by the so-called re-torque shall be ignored at this point.

Later on increasingly used nutrunners with shut-off automatism accrued the advantages that torque was presettable in closer tolerances, that torque was measurable and documentable by transducers and electronic sensors, and that the noise level was considerably lower. Certainly it is useful for manufacturing when the tools stopp automatically at accurate torque and required clamp force, because the risk on human errors is reduced by automatic shut-off. The price to be payed for this advantage consisted of prolonged bolting times. Namely by lower speed of rotation, heavy weight and large dimensions, that generally necessitated two-hand operation due to the reaction of the tool on the operator at the instant of shut-off.

A solution for all these problems was promised then later on by the impulse wrenches increasingly coming onto the market. Beneath the high operation speed they also provide the control of torque. The tool itself is small, leightweight and applicable for one-hand operation. A further advantage is the reaction-freeness of the Yokota impulse wrench. Tissue disease like RSI will be avoided in comparison with other pneumatic nutrunners. Using Yokota impulse wrenches reduces afflictions of the operators and the corresponding financial risks to a minimum.

Primarily on mid-range torque values mainly applied in the automobile industry, the advantages of impulse wrenches are significant:

- Low noise level

- Low vibration

- High torque repeatability at high bolt speed

- Reaction-free

Because of the strong supporting moments with the angle nut runners these were replaced in the automobile industry nearly completely by other tightening systems. American and European manufacturers developed torque angle of rotation nutrunners with shut-off or with computer-control. The Japanese industry rated such tightening systems as unsuitable because of the high price, the large weight and the too high accuracy (!). The tightening time however is of far higher priority for the Japanese industry. Impulse nutrunners, with or without electronic control, in their understanding would by far fulfill the accuracy requirements. Moreover, such a system must be reasonably related to the quality of the screws and parts. It hardly makes sense to use highly exact screwing systems if the screws themselves have far larger tolerances and thus the completely outweighing portion of inaccuracies to cause. Regarding in the automobile industry occurring safety-relevant screw connections (A-joints), it is of crucially higher importance to record a 100% documentation of all safety-relevant screw connections in writing and/or dataelectronically for each mounted vehicle.

Computer-Controlled Impulse Tools

A prejudice, that is still widespread in the French and in the German automobile industry, exists in the opinion that the torque of an impulse nutrunner is not measurable with the torque measuring systems offered on the market, because they obviously were all voted on screwdrivers and angle nutrunners. Although it is outdated long, this before times correct argument also today is still stated by many users against the use of impulse nutrunners – particularly with safety-relevant screw connections. This opinion in practice however is verifiably disproved the measuring systems offered by Yokota as well as when using the recent test systems of the British measuring technique specialist Crane.

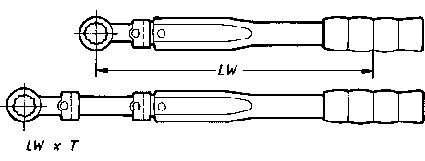

The problem was solved by the computer-controlled system nutrunner developed by the company Yokota – a system, which is based on torsion of the drive shaft, and conducting a group counting. For measuring the torque the Yokota system nutrunner uses a sensor in the pulse mechanism, which by means of strain gauge transforms the torsion of the drive shaft into electrical signals, which are then transmitted to the control unit. Torque and pulse number can be controlled, checked and printed out or exported to the computer with the YETC. The electronically controlled hydraulic impulse nut runner works with a very high number of impulses. Thus further advantages result:

- A screwing procedure transacted with a system nut runner requires approx. 2 seconds and can be implemented with one hand also still at a tightening torque of 600 Nm.

- Computer-controlled tightening systems offer short screwing times at low costs.

For the Japanese automobile industry it is characteristic that relatively simple however fast performing tools are used for assembly. The best proof for it is that the Japanese automobile industry in strong measure applies impulse nutrunners and screwing systems of Yokota.

Re-torque Angle of Rotation

In the automobile industry numerous torque wrenches are in use, which are used to "re-torque" bolt connections accurately on the demanded torque value. This processing step can be saved by a system nutrunner. Routine controlling of the bolt connections tightened with system nutrunners is randomly made with torque measuring wrenches. In the same way this is handled when using torque angle of rotation nutrunners. This approach to examine bolt connections from handheld screwing systems was generally usual and appreciative practice in the automobile industry. A meaningful relation between the torque accuracy and the firmness of a bolt connection however can only be made by determination of the apparent yielding point of a screw. This is technically possible, execution conditionally however high work expended and is therefore very cost-intensive. A further reason for the grasp to the Yokota impulse nutrunner is thus the maximum clamping force with minimum loosening risk.

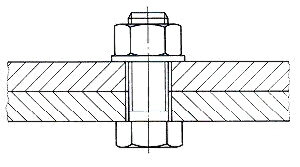

With bolt connections clamping is most important – thus the axial tension in the pin, which ensures the cohesion of the parts. The way to the correct clamping force leads across the attitude of the starting torque after the characteristic values of the screw. In practice it shows up that after tightening rather high setting losses arise. Often this reduces in the long run the tension desired substantially. The experience shows, and lab tests confirm this, that the setting losses are substantially larger with a screw tightened with a angle nutrunner than after the use of an impulse nutrunner. Reason for it is that with the application of an impulse nutrunner while tightening the screw itself is shifted into a condition of vibration. Setting takes place here to a large extent already during bolting. In addition, with handheld tools the application of the angle of rotation is afflicted with many uncertainties.

Yokota differently solves the problem of pulling tight by a certain angle of rotation. Pulling tight takes place via some additional impulses after reaching the adjusted torque, the so-called afterpulses. Additionally between one to fifteen impulses can take place. Beside the vibration when tightening setting losses are compensated to a large extent when tightening by this afterpulsing. Hereby a substantial demand of the automobile industry is fulfilled. Moreover there is the possibility of hundred percent control and documentation. In addition optical and acoustic warning signals can be integrated separately into the system or together and it is possible to define so-called bolt groups. For example twelve screws can be defined as a group. If with tightening a bolt is forgotten then, the system refuses the transition to the next group of screws.

Recommendation

Only a 100 % documentation of all screw connections offers demanded security. All torque values must be traceable; only like that it is ensured that each screw was tightened. This means that impulse nutrunners should be used in the automobile industry in accordance with following recommendation:

- VDI 2862 category C: Standard impulse nutrunner with high torque repeatability

- VDI 2862 category B: Shut-off impulse nutrunner or Poka Yoke nutrunner

- VDI 2862 category A: Computer-controlled system impulse nutrunners

A meaningful and appropriate relation is ensured in this way between accuracy, screwing time and conditions of work for the operator. Yokota used up itself the continuous technical advancement, the observation of the production processes, the efficiency improvement as well as the increase of speed and security - for the advantage and benefit of the automobile industry.