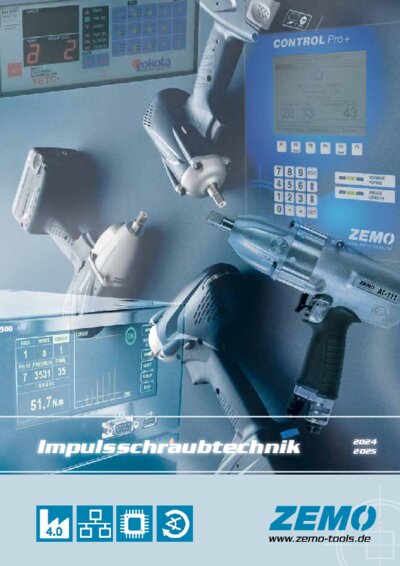

Impulse Tools

Yokota impulse wrenches are sophisticated tools with hydraulic power transmission. Unlike rotary wrenches or impact wrenches, this transmission is indirect, as the drive motor (pneumatic or electric) is not mechanically connected to the drive shaft. The motor transmits its power to the impulse cylinder, where a special hydraulic fluid is briefly compressed. The pressure impulse generated in this way is transmitted to the drive shaft without impact.

In addition to its high working speed, an impulse wrench also offers torque control and, most importantly, has virtually no reaction torque. This means that the impulse screwdriver can be operated with just one hand and no counterholders such as carbon arms or similar are required. The low setting behavior is also particularly effective in terms of quality, as the screw/nut has to “work” during the screwing process. This achieves a higher preload force than with other methods.

Impulse wrenches are preferred for screwdriving operations in production lines where short cycle times are required. The one-handed tools are fast, powerful, and easy to handle, and they are virtually recoil-free. In addition, impulse wrenches have a low noise level, low vibration, and a favorable weight/performance ratio.

Evaluations of assembly processes in automotive production show that tightening screw connections takes up about 1/10 of the total assembly time. Working with faster tools can therefore measurably accelerate production cycles.