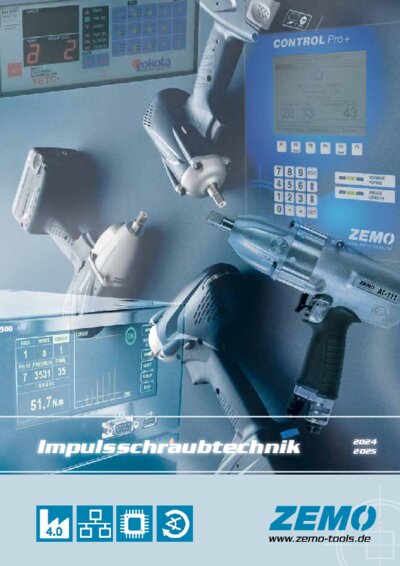

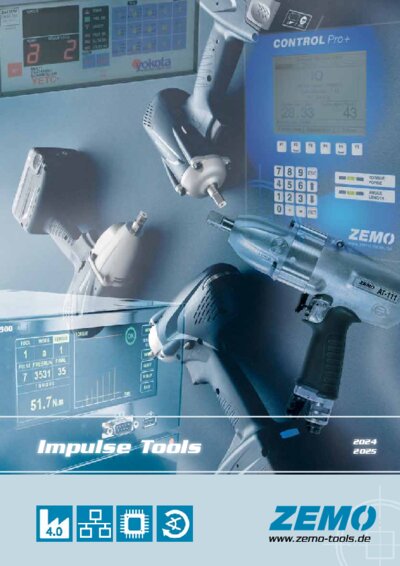

Transducerised Battery Impulse Tools with Angle Monitoring

Product liability is a very important issue for automotive manufacturers. Safety-related bolt connections in particular must therefore be tightened to the correct clamp force. For this reason 100% documentation isn't optional – it's essential!

This is achieved using an electronically controlled impulse wrench with a built-in torque transducer and angle sensor on the main shaft, which is connected to a control system. If the control system detects that the tightened connections do not meet the specified parameters, it can send a signal to stop the line and the bolt connections can be checked manually. This zero-error system is suitable for the PokaYoke strategy.

YOKOTA impulse wrenches are widely used for tightening work in the assembly industry, where accurate torque tolerances are important. Impulse tools are light, powerful, compact and – very importantly – have no kick-back.

Features

- Freedom of movement by use of batterie

- Low weight / torque ratio

- High speed fastening

- Acoustic and LED signals for tightening status indication

- No Kickback

- Brushless DC drive, RPM freely adjustable

- Hybrid technology

- 100% check on tightening abnormalities