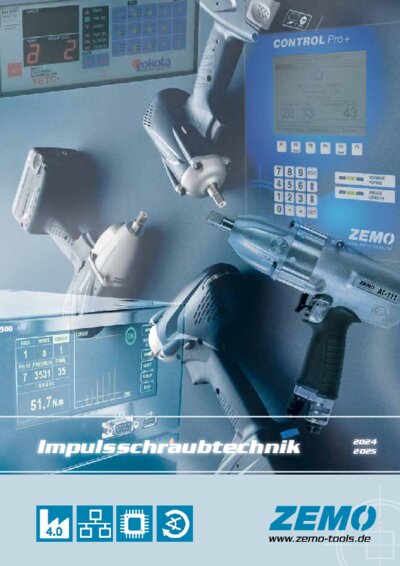

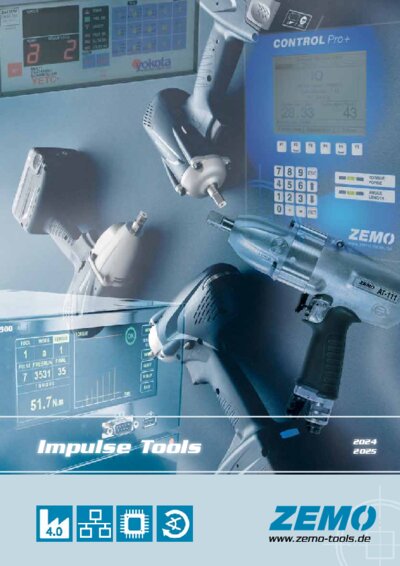

Electric Impulse Tool System with Torque Control & Angle Monitoring

The future is electric. Controlled impulse screwdriver with built-in torque and angle sensors, which significantly reduces energy costs while maintaining accuracy and work efficiency. (Compared to air screwdrivers).

The electric e-M1100 can reduce energy consumption by 96% compared to our air model TKa-1110 while delivering the same performance. Air equipment such as air compressors, air lines and solenoid valves are not required. Oil mist, which was unavoidable with compressed air tools, is eliminated, resulting in an improved working environment.

Detects double tightening and abnormal tightening. In addition to the torque sensor for torque control, an angle sensor is installed to monitor the rotation angle and time. The bolting result is controlled/monitored from three directions: torque, rotation angle and time, enabling high-precision detection of double tightening and abnormal tightening.

- Yokota electric system screwdriver control

- Torque/pulse count-controlled shutdown

- Versatile parameterisation

- Touch panel colour display

- PC or PLC connection via USB, RS-232C, I/O

- Optional with LAN port RJ45

- Yokota electric system impulse screwdriver e-M

- Newly developed outer rotor servo motor

- Powerful twin-blade impulse cell

- Contactless rotation angle sensor

- Acoustic/optical display of OK/NG

- Torque levels 10 / 35 / 60 / 90 Nm