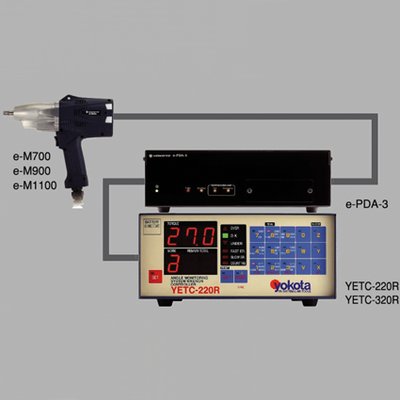

Electric Impulse Tool with Torque Control and Angle Monitoring

The YOKOTA electric system wrenches with integrated torque transducer and angle sensor offer a large reduction of energy consumption, a high degree of accuracy and fantastic work efficiency.

Faulty tightening detection with maximum accuracy due to the use of an integrated torque transducer and also an integrated angle sensor. Torque transducer and angle sensor located directly at the front of the main shaft, giving the best accuracy of measurement. The angle sensor is an extremely compact (PAT) rotary encoder that detects both angle as well as direction by 1 degree, signal transmission contactless.

Due to the newly developed outer rotor servo motor and the composite body, the Yokota system e-wrench has the lightest weight in its class. For cooling of the motor it is equipped with a fan that

reduces motor size (and weight at the same time). For cooling of the impulse unit it is equipped with a separate fan.

The reaction forces are close to zero due to the use of the oil impulse mechanism, even at high torque bolt tightening. Compared with older models, the number of bolt tightening is improved to 20 bolts/minute.

Motor speed freely adjustable in the controller. For three different speed stages: Start of trigger / Run down / Final tightening. Special feature to prevent cross threaded tightening: reversely rotating a bolt to a preset angle at the start of tightening.

Accurate Tightening & Operator Comfortability

Energy Saving Electric Drive

| Model | Item No. | Torque Range [N·m] | Free Speed [1/min] | Bolt Capacity | Weight [kg] | Sq.Drv [inch] | Noise [db(A)] |

|---|---|---|---|---|---|---|---|

| e-M 500 | 430700 | 3 - 10 | 300 - 4800 | M5 - M6 | 1.68 | 3/8 | 75 |

| e-M 700 | 430710 | 7.5 - 35 | 300 - 4800 | M6 - M8 | 1.68 | 3/8 | 75 |

| e-M 900 | 430720 | 30 - 60 | 300 - 4800 | M8 - M10 | 1.76 | 3/8 | 78 |

| e-M 1100 | 430730 | 50 - 90 | 300 - 4800 | M10 - M12 | 2.04 | 1/2 | 80 |

All specifications without guarantee, errors and omissions excepted.