Automatically Set the Correct Torque with Each Bit

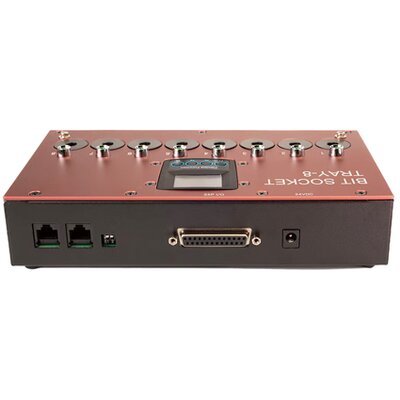

The bit socket tray is an error-proofing solution that minimizes the risk of errors by automatically selecting the correct torque according to the socket or bit selected. The device connects to ECD, ECTD, or MDC controllers and Posi Touch position control torque arms system. It will improve productivity and reduce operator errors. Saves downtime by automatically changing program settings for multiple fastening strategies.

Minimize the risk of fastening errors and improve production efficiency with this intelligent error-proofing solution. This system automatically selects the correct torque or preset program based on the bit or socket chosen – no manual input required.

When an operator removes a tool bit from the tray, the system instantly recognizes the selection and adjusts the controller settings for that specific fastening task. This eliminates guesswork, prevents operator errors, and ensures consistent quality across multiple sequences and workflows.

With multiple sensor-equipped bit holder ports, the tray supports a wide range of fastening operations and helps streamline production with faster changeovers and increased cycle times.

Error-Proofing Bit Socket Trays

- Enhances productivity and reduces operator error by enforcing standardized assembly conditions before allowing the manufacturing process to continue.

- Increases cycle time by automating program changes across workflows.

- Seamless integration with ECD, ECTD or MDC controllers and Posi Touch position control torque arms system.

- Multiple bit holder ports with built-in sensors for flexible setup.

Colour Coded Bit Socket Tray

- Error Reduction: Eliminates manual selection mistakes and ensures the correct torque is always applied.

- Time Savings: Automatically switches programs, reducing the need for operator intervention and cutting down cycle time.

- Higher Throughput: Speeds up multi-sequence fastening tasks, supporting more efficient workflows.

- Colour Sensors: Use a colour-coded process for visible and easy-to-understand bit identification.

Features & Benefits

- Error Reduction: Eliminates manual selection mistakes and ensures the correct torque is always applied.

- Time Savings: Automatically switches programs, reducing the need for operator intervention and cutting down cycle time.

- Higher Throughput: Speeds up multi-sequence fastening tasks, supporting more efficient workflows.

- Colour Sensors: Use a color-coded process for visible and easy-to-understand bit identification. (Model 5C)

- Improved Quality: Ensures consistent fastening torque across assemblies for higher product reliability.

- Operator Confidence: Simplifies the process, allowing operators to focus on assembly rather than settings.

- Flexible Integration: Easily connects with existing Mountz torque control systems for a smooth upgrade path.

- Connects to ECD, ECTD or MDC controllers and Posi Touch position control torque arms system.

- Bit holder ports with sensors.

- Bit Holders Included: 7.5mm

- 1.3” AMOLED colour display

Scope of Supply

- Bit Socket Tray

- SMPS Adapter DC 24V 1A (#310102)

- AC 120V Power Cable

NOTE: for 230V Power Cable w EU plug, order #310110 (not included)

Order Codes

- M310185 = Bit Socket Tray – 4 Bit Holders

- M310186 = Bit Socket Tray – 8 Bit Holders

- M310187 = Bit Socket Tray – 12 Bit Holders

- M310188 = Bit Socket Tray – 16 Bit Holders

- M310250 = Bit Socket Tray with Colour Sensors – 5 Bit Holders

- M310112 = Cable 25P I/O ECD, ECTD, and MDC Controller to Auto Bit Socket Tray – 3m

- M310115 = Cable 25P I/O ECD, ECTD, and MDC Controller to Auto Bit Socket Trays – 5m

Options / Accs / Spares

- M310104 = Bit Holder for Bit Socket Tray - Hole Size 18mm

- M310105 = Bit Holder for Bit Socket Tray - Hole Size 15mm

- M310106 = Bit Holder for Bit Socket Tray - Hole Size 10mm

- M310107 = Bit Holder for Bit Socket Tray - Hole Size 7.5mm

- M310108 = Bit Holder for Bit Socket Tray - Hole Size 3mm

- M310109 = Bit Holder for Bit Socket Tray - Hole Size Plain (blind)