Ideal for Tightening Verification Assembly Processes

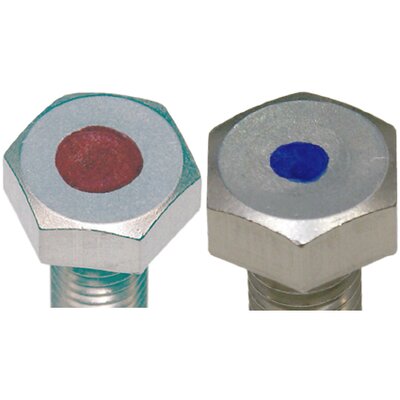

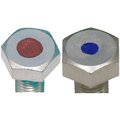

Pokayoke (error-proofing) marking torque wrench. Lets you make direct visual checks for bolt tightening errors. When the adjusted torque value is reached and the wrench clicks, the bolt head is marked. So tightening and marking is done in a single operation. Marking is not done until set torque is achieved. Marking stays on by use of quick dry ink.

Ink cartridges can easily be installed in the special socket wrench. One cartridge filling is sufficient for appr 5000-6000 stamping processes. Height of the stamp is adjustable (±5 mm).

Pre-Lock Version

The Pre-Lock type is equipped with internal scale. Allows adjustments of the tightening torque on the tool. The set torque is visible via a small scale window in the handle. Setting torque can be operated by an attached hex key to avoid torque change by human mistake. The torque adjustment hex key is a standard accessory. Suitable for applications with changing torques (service jobs).

Features

Scope of Supply

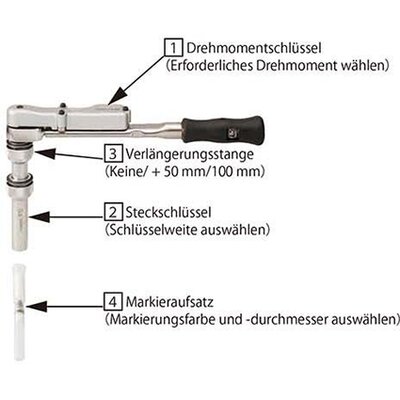

Compose Your Marking Model

Options / Accs / Spares

| Model | Item No. | Torque Range [N·m] | Graduation | Length [mm] | Weight [kg] |

|---|---|---|---|---|---|

| MPQL50N | T212501 | 10 - 50 | 0.5 | 246 | 0.7 |

| MPQL100N4 | T212504 | 20 - 100 | 1 | 320 | 1.0 |

| MPQL140N | T212507 | 30 - 140 | 1 | 385 | 1.1 |

| MPQL200N4 | T212510 | 40 - 200 | 2 | 418 | 1.8 |

| MQL280N | T212513 | 50 - 280 | 2 | 692 | 2.6 |

| Model | Item No. | Torque Range [lbf·in] | Torque Range [lbf·ft] | Graduation | Length [mm] | Weight [kg] |

|---|---|---|---|---|---|---|

| 450 MPQL-A | T212503 | 100 - 400 | – | 5 | 246 | 0.7 |

| 900 MPQL4-A | T212506 | – | 15 - 75 | 1 | 320 | 1.0 |

| 1400 MPQL-A | T212509 | – | 30 - 100 | 1 | 385 | 1.1 |

| 1800 MPQL4-A | T212512 | – | 30 - 130 | 2 | 418 | 1.8 |

| 2800 MQL3-A | T212515 | – | 60 - 300 | 3 | 692 | 2.6 |

Length/weight without accessories.

Data according to specifications by the manufacturer. It is recommended to primarily use in moderate performance range (approx. 1/3 to 4/5 of rated capacity). If you regularly worked close to the limit of load (max capacity), a larger model or tool might be more advisable.

All technical data without guarantee, errors and omissions excepted.