Ideal for Tightening Verification Assembly Processes

Pokayoke (error-proofing) marking torque wrench. Lets you make direct visual checks for bolt tightening errors. When the adjusted torque value is reached and the wrench clicks, the bolt head is marked. So tightening and marking is done in a single operation. Marking is not done until set torque is achieved. Marking stays on by use of quick dry ink.

Ink cartridges can easily be installed in the special socket wrench. One cartridge filling is sufficient for approximately 5000-6000 stamping processes. Height of the stamp is adjustable (±5 mm).

Preset Version

Preset type clicker wrench without scale; fixed pre-adjusted torque. Ideal for successive tightenings at the same torque (production line). A suitable tester and adjusting adapter (see below) are required to set the torque. Please specify desired operating torque when inquiring/ordering (e.g.: MQSP140N X T110Nm).

Features

- Compliant with EN ISO 6789:2017.

- Ratchet head w 24 teeth and 15° operating range.

- Tightening and marking in a single operation.

- Stamp height adjustable (±5 mm).

- Quick dry ink.

Scope of Supply

- Torque wrench MQSP

- Operating manual

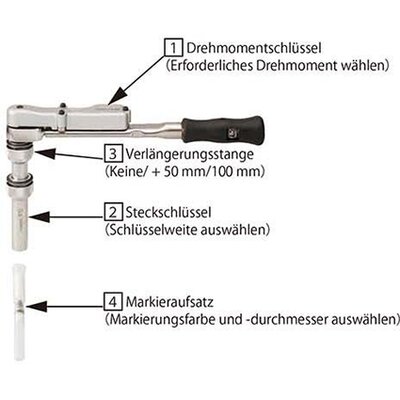

Compose Your Marking Model

- Marker Head ('Stamp & Cartridge'):

- No. 2780 = MK53RB ø 5 mm for red or blue, w A/F 16mm or less

- No. 2782 = MK53WY ø 5 mm for weiß oder gelb, w A/F 16mm or less

- No. 2783 = MK93RB ø 9 mm for red or blue, w A/F 17mm or larger

- No. 2785 = MK93WY ø 9 mm for white or yellow, w A/F 17mm or larger

- Refill Ink:

- T286084 = blue (20 ml)

- T286083 = red (20 ml)

- T286074 = white

- Special Sockets for Models MQSP50N...200N:

- No. 2700 = 4MH-10 mm, max 25 Nm

- No. 2701 = 4MH-12 mm, max 35 Nm

- No. 2702 = 4MH-13 mm, max 40 Nm

- No. 2703 = 4MH-14 mm, max 60 Nm

- No. 2704 = 4MH-16 mm, max 70 Nm

- No. 2705 = 4MH-17 mm, max 110 Nm

- No. 2706 = 4MH-18 mm, max 120 Nm

- No. 2707 = 4MH-19 mm, max 170 Nm

- No. 2709 = 4MH-22 mm, max 190 Nm

- No. 2710 = 4MH-24 mm, max 200 Nm

Options / Accs / Spares

- Solvent (for rinsing the needle if you are using an injector to refill it):

- T286076 = for W/Y

- Replacement Felt Tips (Pk 10 ea):

- No. 1775 = for MK ø 5 mm R/B

- No. 775 = for MK ø 5 mm W/Y

- No. 1776 = for MK ø 9 mm R/B

- No. 1777 = for MK ø 9 mm W/Y

- Extension bar (either):

- No. 1749 = 50 mm MQSP50...200N

- No. 1748 = 100 mm MQSP50...200N

- Marker Guide:

- No. 2786 = required only when using ø 5 mm Marker Head #1780 or #1782 with socket A/F 17 mm to 30 mm.

- No. 2787 = Guide Set for red/blue, consisting of #2786 plus #1780

- No. 2788 = Guide Set for white/yellow, consisiting of #2786 plus #1782

- Adjusting/calibrating Adapter:

- No. 817 = applicable for MQSP50N

- No. 818 = applicable for MQSP100N...200N

- Ratchet Repair Kits (RRK)

NEW: Wireless Option

- Marking torque wrench "MQSPFD" equipped with the compact FD radio transmitter, with which you can ensure in a later process or even after shipment that tightening was correctly performed. Can be custom-made after receiving an order.

- Defect prevention with a large pass/fail decision LED. Transmission error or tightening torque defect can be immediately known from this large LED: Blue = OK, red = NG.

- The torque wrench transmitter can be set with a 7-digit alphanumeric character or a 3-digit ID, so the torque wrench used for tightening can be specified, which leads to traceability.

- Conforms to wireless technical standards in Canada, China, the EU, India, Indonesia, Japan, Malaysia, Mexico, Russia, Singapore, South Korea, Taiwan, Thailand, the USA, and Vietnam. However, certain restrictions apply regarding export procedures to Indonesia (SDPPI), so please check with Tohnichi for more information, if applicable.

- If required, please ask us for further information on the R-CM wireless receiver with M-FD radio module. (Available as single components, or as a set.)